A design for the mould is produced first, whereupon negatives are milled from solid blocks of metal. These negatives are then used to produce the aluminium castings, which the foundry uses to produce imprints.

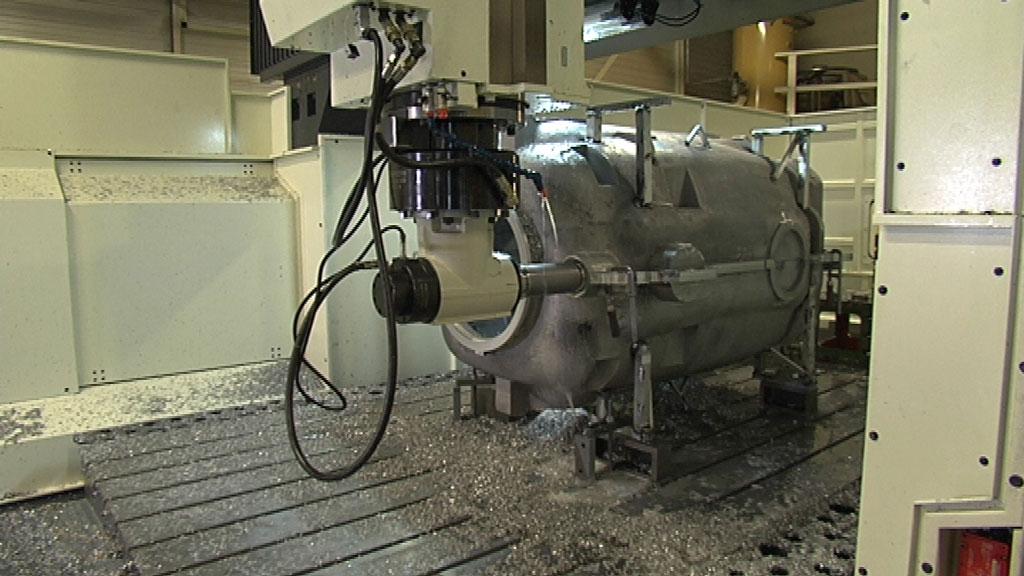

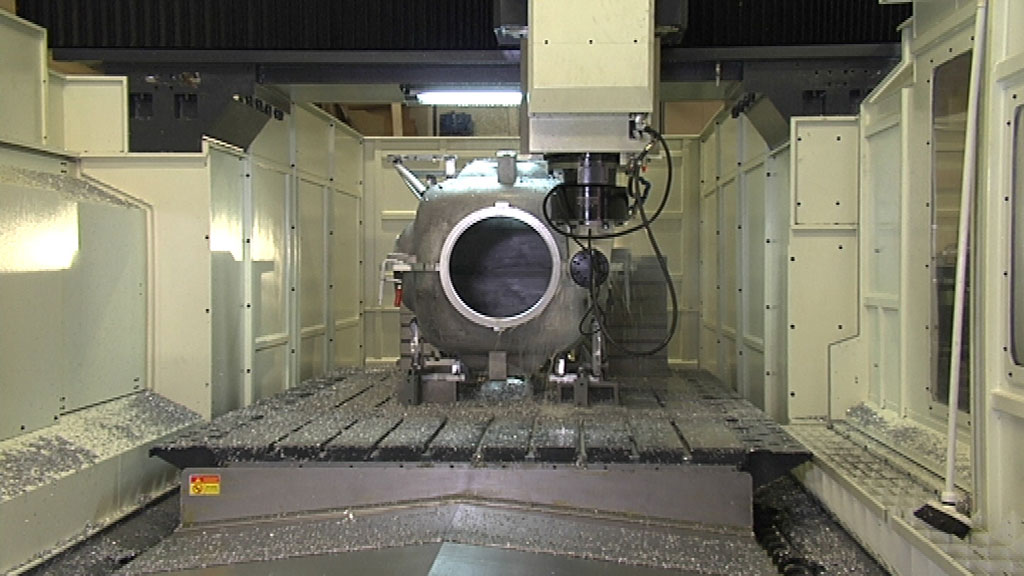

In the event that the model is to be directly milled from a block of aluminium, drawings of the mould are produced first. The design is then presented to the customer for approval. The CNC technology applied vouches for both the high quality of the mould and a perfect seal.

During the design process, close attention is paid to the location of the clamps and the further construction of the mould frame.

Once the mould has been milled, a surface treatment is applied. This surface treatment ultimately determines the quality of the mould. Modelmakerij Hengelo can apply all sorts of surface treatments, including the following: bead blasting, tempering, surface coatings, such as Silver Shadow, Teflon or Diamond Shield. Tempering offers the mould extra protection.